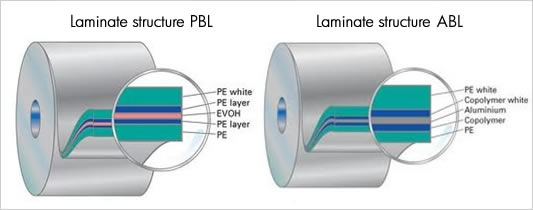

In early 2014, the company expanded its product portfolio by adding laminated tubes containing aluminum barrier (ABL) and plastic barrier (PBL) EVOH.

Laminated tubes with EVOH barrier (Laminated Plastic Barrier) have the advantages of plastic tubes (flexibility and ability to return to their original shape) and with the addition of EVOH barrier they become resistant to the penetration of unwanted substances and gases into the product. The two barriers (ABL-PBL) protect the product from the influence of external factors such as UV rays, air and moisture as well as from oxidation of the product or the escape of aromatic substances from outside the tube.

New possibilities for plastic welding: With a simple pressure on the tube, the edges of the tube sides are welded and almost invisible (the tangent sides are not visible) which allows the printing processes to cover the entire surface of the tube.

Types of Laminated Cover

ABL – Aluminum Barrier Sheet

PBL – EVOH Plastic Barrier Sheet

Available Colors of Material:

White

Silver

Other Colors (Special Request According to Customers’ Desire)

PBL (Aluminum Barrier Sheet) Thickness:

(350my/25my EVOH- 300my/25my EVOH- 300my/15my EVOH- 400my/9my EVOH)

Production Process

The tube sheet is made of flat stamped strip. The laminated sheets used by our company come from the world’s best manufacturers of this material. The sheet structure consists of 5 layers (polyethylene – adhesive layer – barrier (aluminum or EVOH) – adhesive layer – polyethylene).

The laminated strip is sealed and formed into a cylinder according to the required diameter and then cut into lengths suitable for the size of the materials to be packaged. The upper head of the tube is heated and welded. It may be covered at the top of the head with an aluminum film for better protection of the product. The final stage is tightening the cap chosen by the customer.

Cosmetics Branch

Laminated tubes in the cosmetics sector are often used for toothpastes, hand creams, hair removal creams, shaving creams, cosmetic peeling creams, body creams, conditioners and shampoos, etc.

Our packages meet the most demanding requirements of cosmetics companies, both domestic and foreign.

Our laminated tubes can be coated, for example. Adding a coating containing special additives that emit the fragrance of the product. It is an ideal way for the customer to get familiar with the fragrance of the product without having to open the tube. It also gives the content of the advertisements flowing from the packaging.

A way of decoration is to get a gloss effect. Special varnish additives can be used, which gives the printing an attractive shine.

Advanced means of decorating some cosmetic tubes use matt and glossy varnishes to get out the depth of the color (glossy) or (matte). Combining two types of varnishes enables us to achieve wonderful visual effects on the printing.

In our offer there is also the possibility of printing plates with fluorescent paints that have features of glowing in the dark. This way of decoration makes your products easily visible even in dim light.